Inspiration Begins When Ideas Become Reality

When designing, I am not so much interested in trends as in creating uniqueness, daring to dazzle with color, size and design.

Designing for me is a four-part process:

- Analyze the customer’s needs and wants.

- Organize the information for the project goals and divide it into the various design processes.

- Personalize the design into creative expression.

- Conceptualize the big picture, visualizing the end from the beginning.

These steps don’t necessarily happen in sequential order. It may be somewhat simultaneous, but they all have to happen for a design to become a reality.

Finding the Story

Inspiration comes from different sources. It could be a special occasion, a descriptive word, a shape, a special meaning, but all lead to a concept. My personal interviews with clients give rise to these inspirations.

I ask clients questions like:

- What in life is important?

- Where do you find your inner strength?

- Is this piece to commemorate an achievement?

- What do you talk about when you need to break the ice in a group?

- What makes you you?

- How is the jewelry to be worn?

- Do you like yellow or white metals?

- Preferences for particular stones or stone colors?

- Simple designs, ornate, large jewelry or minimal size?

All of these questions help me understand the specific wants and desires of a client, and helps me to match the design aesthetic and specific flare that the piece or pieces will showcase.

From Story to Sketches

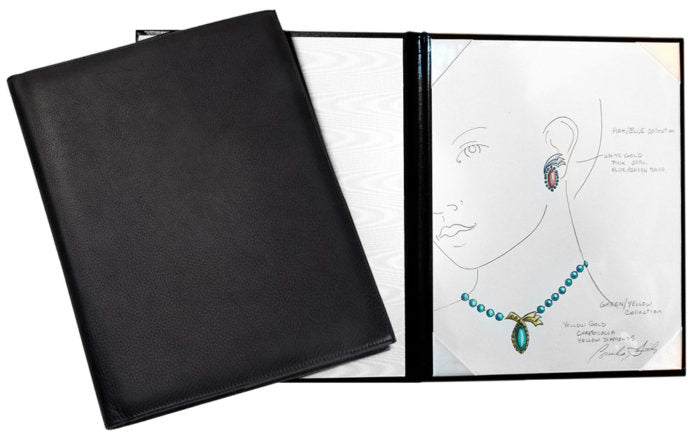

With inspiration, background and ideals in mind, I continue with simple pencil sketches. After a semblance of direction is determined, I draw in ink and add color. This is the point where changes should be made to be most cost effective.

Prototype & Fabrication

Jewelry can be created through lost wax casting, hand fabrication, or a combination thereof, depending on the intricacy of the design. A wax can be hand carved or 3-D printed from a CAD file, both created from my original hand-drawn sketches. This exciting process lets my clients be intimately involved in their jewelry creation. Any changes made by the client are preferable made during the sketching process for cost effectiveness. If the wax is carved by hand, it has a one-time use as it is melted during the casting process. A wax generated from CAD can be reprinted from the file if necessary. I utilize a team of highly skilled craftspeople and all production is overseen by me personally.

Finishing Your Custom Piece

After casting or fabrication, I thoroughly enjoy and relish the experience of pre-finishing the rough metal, setting stones according to design, and then final finishing and polish. I inspect the finish piece one more time and sign showing readiness for presentation to the customer.

As a bonus, customers are presented with the original drawing of their custom heirloom in a leatherette presentation folder as a keepsake.

Are you interested in having a piece made for you or a loved one, please contact me and we can start the conversation!